Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

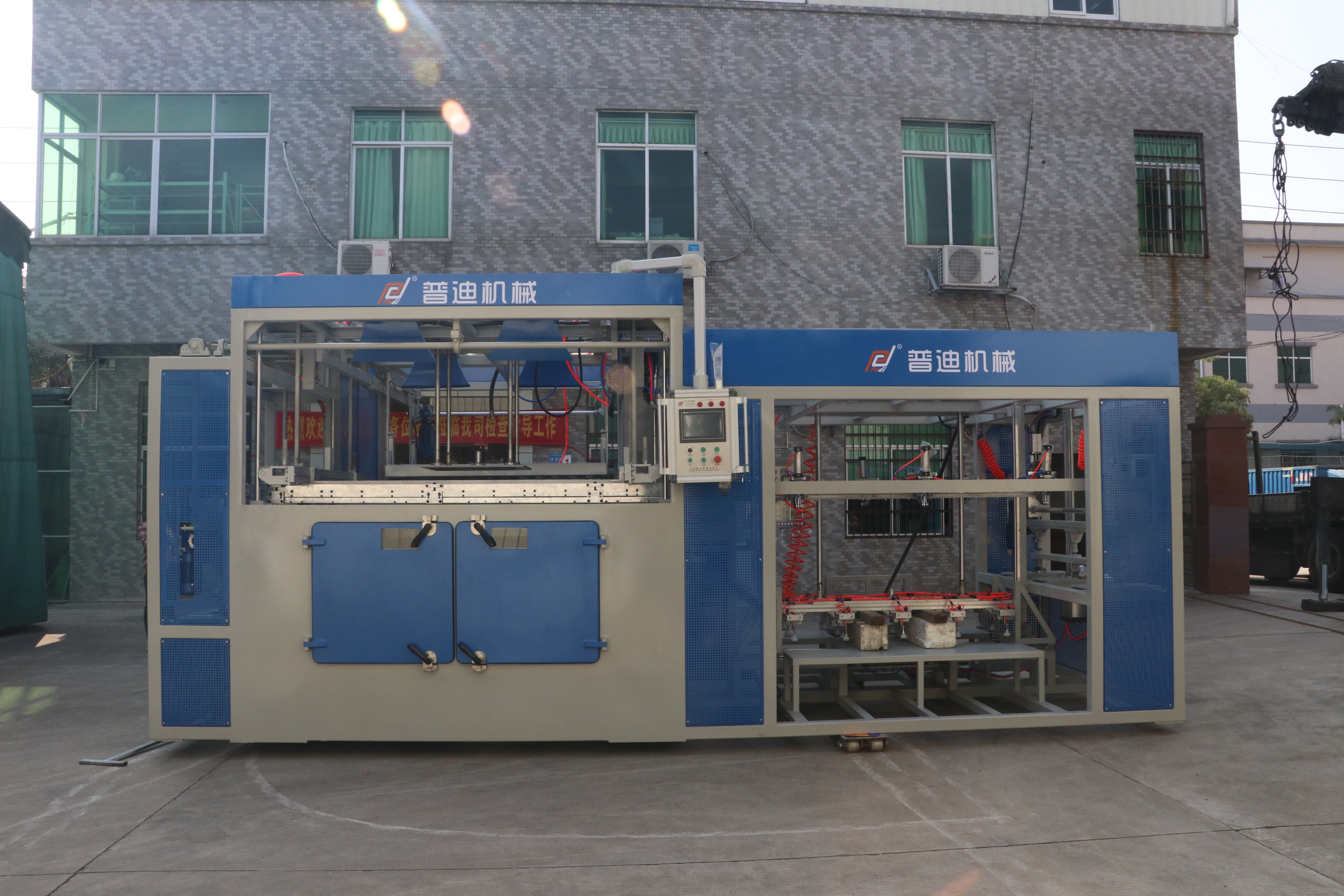

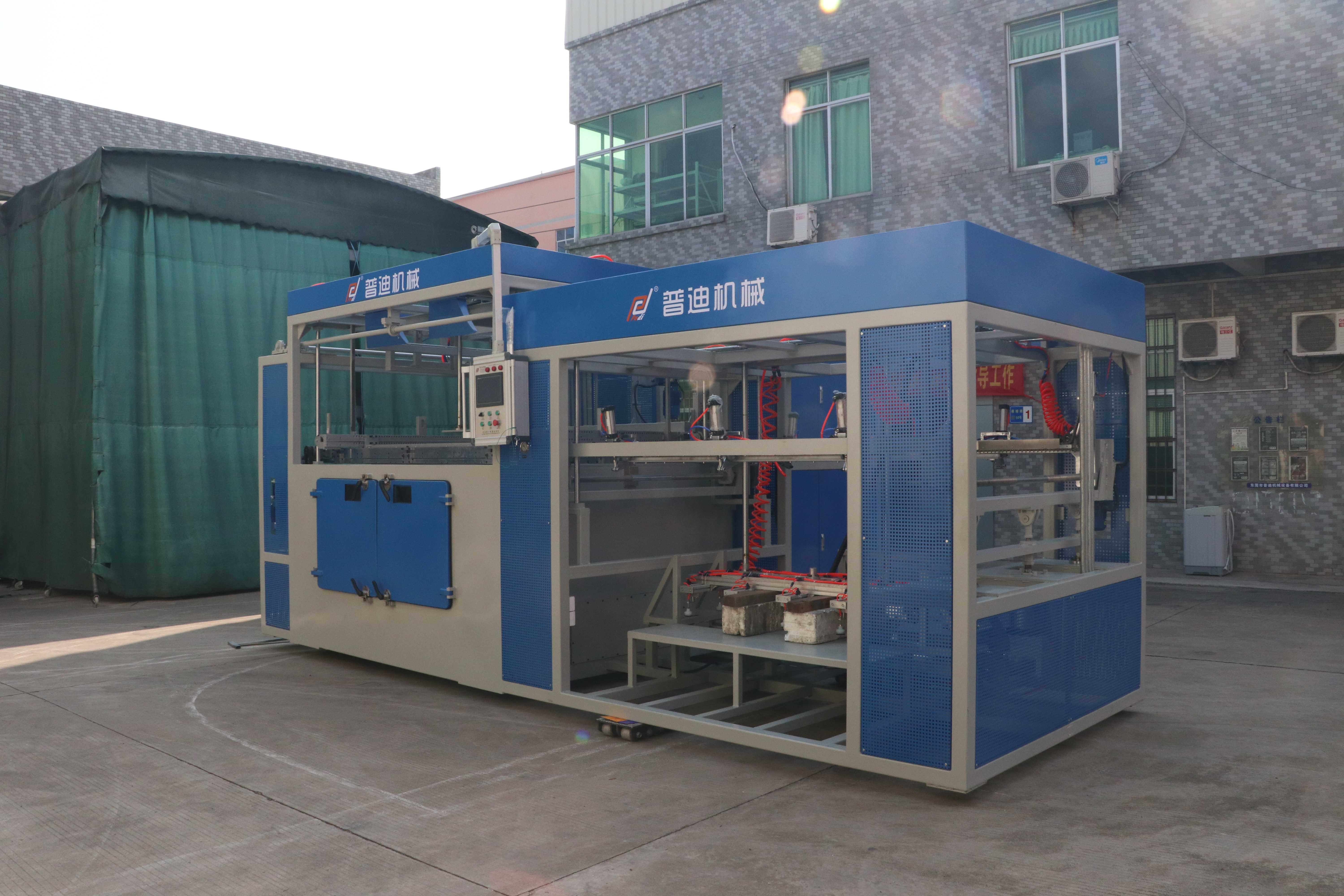

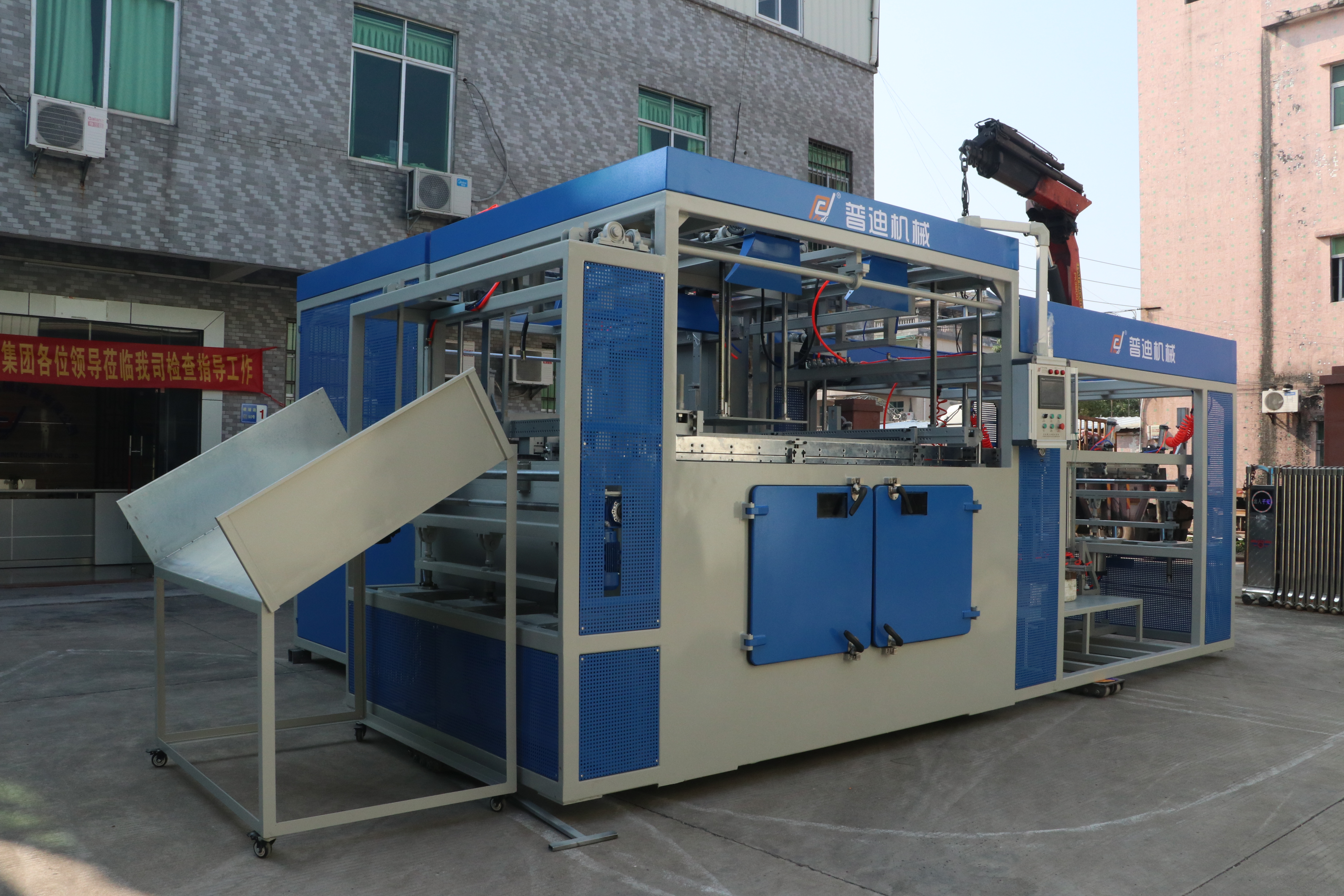

The double station vacuum forming machine can be used in small space, and it can fast work out of the limit of vacuum room. The screen will show the temperature, pressure, and location, so you can freely adjust it. It can keep the heating board in constant temperature to prevent danger. It is suitable for thermoforming of composite materials, carbon fiber, glass fiber, etc.

Multifunctional:

The machine is equipped with a dual station design that allows for the simultaneous forming of two products, increasing productivity and versatility. It can perform multiple forming methods, such as vacuum forming, pressure forming, and twin sheet forming, allowing manufacturers to produce a wide range of products with different shapes and sizes. It can be customized, allowing manufacturers to add features and components that suit their specific forming needs, further enhancing its versatility.

Wide Application:

The machine is capable of performing multiple forming methods, such as vacuum forming, pressure forming, and twin sheet forming, allowing manufacturers to produce a wide range of products with different shapes and sizes. It’s also compatible with a wide range of materials, such as ABS, PVC, PET, and polycarbonate, allowing manufacturers to produce products with different properties and characteristics.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |

Maintenance of the Double Station Vacuum Forming Machine?